Robust Theme

Dec 09, 2019 2020-04-08 7:40Robust Theme

Unleashing the Power of Kaizen: A Comprehensive Guide to Implementing the 5S Method for Continuous Improvement

by Chris Daily

Every organization dreams of smooth operations, peak productivity, and high customer satisfaction. To achieve this, they must embrace a culture of continuous improvement and efficiency. In this context, Kaizen, a Japanese term for 'change for the better,' provides a platform for continuous improvement efforts, fostering a transformative and productive working environment. A key component of the Kaizen culture is the 5S Method, a simple yet powerful tool for process improvements.

Understanding the 5S Method in a Kaizen Event

A Kaizen event, or a Kaizen improvement event, is a focused and structured workshop where cross-functional team members come together to improve an existing process rapidly. Every successful Kaizen event aims to streamline processes, enhance customer satisfaction, and strengthen continuous process improvement. This can be achieved using the 5S Method, Value Stream Mapping, and Preventative Maintenance tools.

Breaking Down the 5S Method in the Context of a Kaizen Event

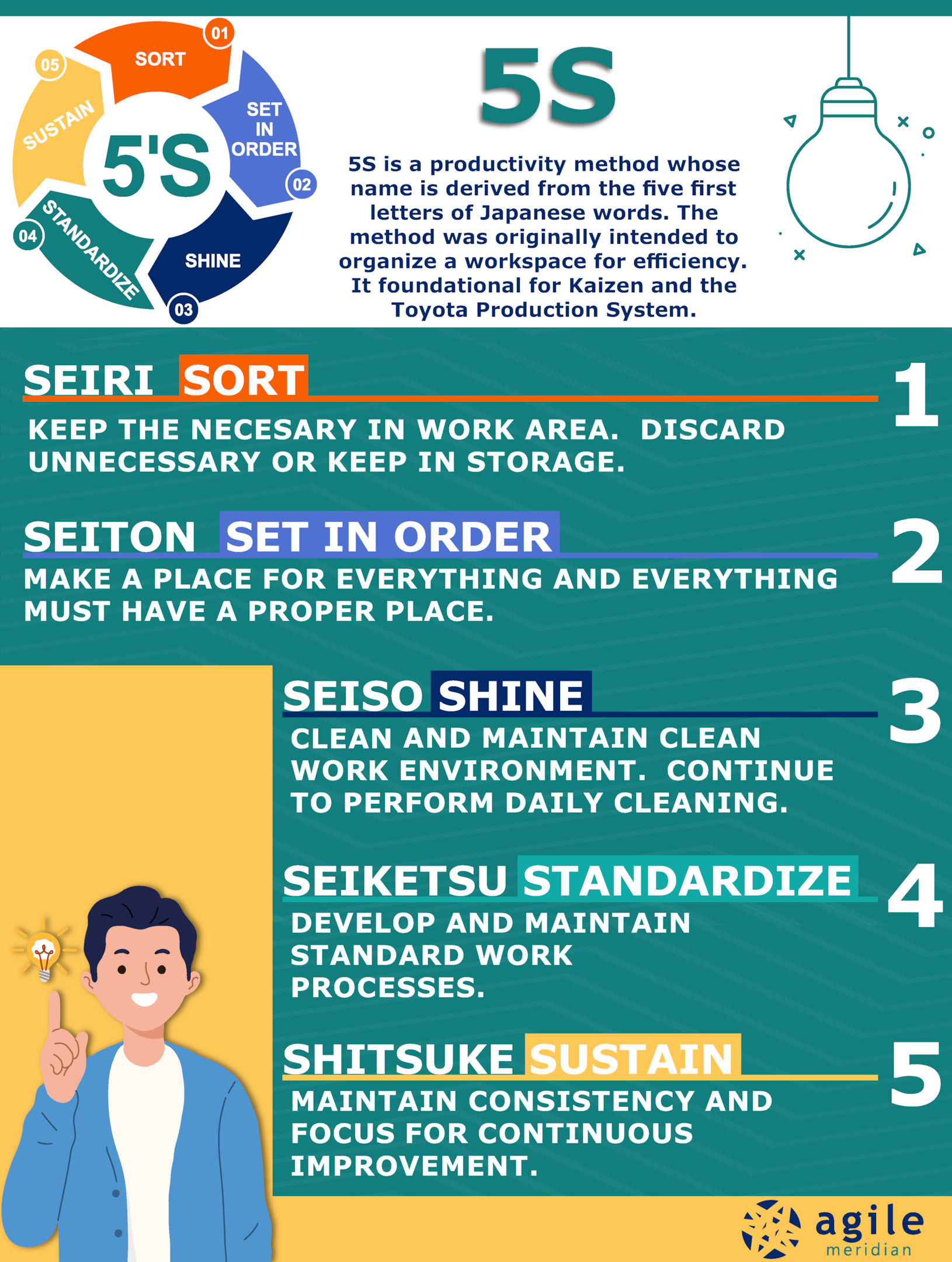

The 5S Method, derived from Japanese terms Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain), offers a framework to organize and manage the workspace efficiently, serving as the foundation for Kaizen events.

Sort (Seiri)

Team members identify and remove unnecessary items from the current process or workspace in the first stage. This step helps declutter the environment and uncovers additional improvement opportunities that may be hidden in the mess.

Set in Order (Seiton)

After sorting comes setting in order, which involves organizing the necessary items for easy access. The goal is to reduce the time spent searching for tools, information, or resources, which directly boosts productivity and streamlines operations.

Shine (Seiso)

This stage entails cleaning and maintaining the workspace regularly. It's not just about cleanliness; a clean environment is conducive to spotting anomalies and malfunctions before they escalate into larger issues.

Standardize (Seiketsu)

This phase involves developing standardized protocols to maintain the sorted and cleaned workspace. It ensures everyone is on the same page and understands the required procedures, contributing to a unified approach to continuous improvement.

Sustain (Shitsuke)

The final stage is about making a habit of the previous four steps. It involves sustaining the newly implemented practices through training, leadership development, and embedding them into the organization's culture.

How a Kaizen Event Works: From Preparation to Implementation

Most Kaizen events begin with detailed Kaizen Event Preparation, including defining the scope of the event, assembling the Kaizen team, and appointing the team leader and the event's executive sponsor. Throughout the event, the team maps the current process through value stream mapping, identifies areas of waste or inefficiency, and devises and implements improvements.

The 5S method becomes instrumental in ensuring a successful event by optimizing workspace management. A typical Kaizen event lasts from a few days to a week, and its success relies on effective cross-functional collaboration and adherence to the selected methodologies, such as 5S.

Suggested Graphic: A timeline illustrating the various stages of a Kaizen event, from preparation to implementation.

The Impact of 5S on Future Kaizen Events

The successful implementation of the 5S method enhances the current process and sets a precedent for improved future events. By incorporating the 5S methodology, team members become familiar with a simple improvement cycle that can be repeated in future Kaizen events.

This continuous process improvement ultimately enhances the quality of the product or service, leading to higher customer satisfaction. Moreover, the culture of Kaizen fosters leadership development among team members, nurturing future leaders who can spearhead the organization's continuous improvement efforts.

Wrapping up.

The 5S method is potent in every successful Kaizen event, driving efficiency, productivity, and customer satisfaction. It encourages team members to take ownership of their workspace, fosters cross-functional collaboration, and ensures continuous improvement - a cornerstone of the Kaizen culture. By applying the 5S method consistently, organizations can reap the rewards of a well-managed and efficient working environment, laying the groundwork for success in current and future Kaizen events.

If you want to learn more about Kaizen, check out our free eBook "Kaizen: Continuously Improving,"

Thanks for reading.

Chris

Originally posted on Medium.